The anode off-gas recirculator, the so-called fan-turbine unit (FTU), is designed and optimized to increase the efficiency and lifetime of Solid Oxide Fuel Cell (SFOC) systems, or to enhance liquid-fueled fuel cell systems.

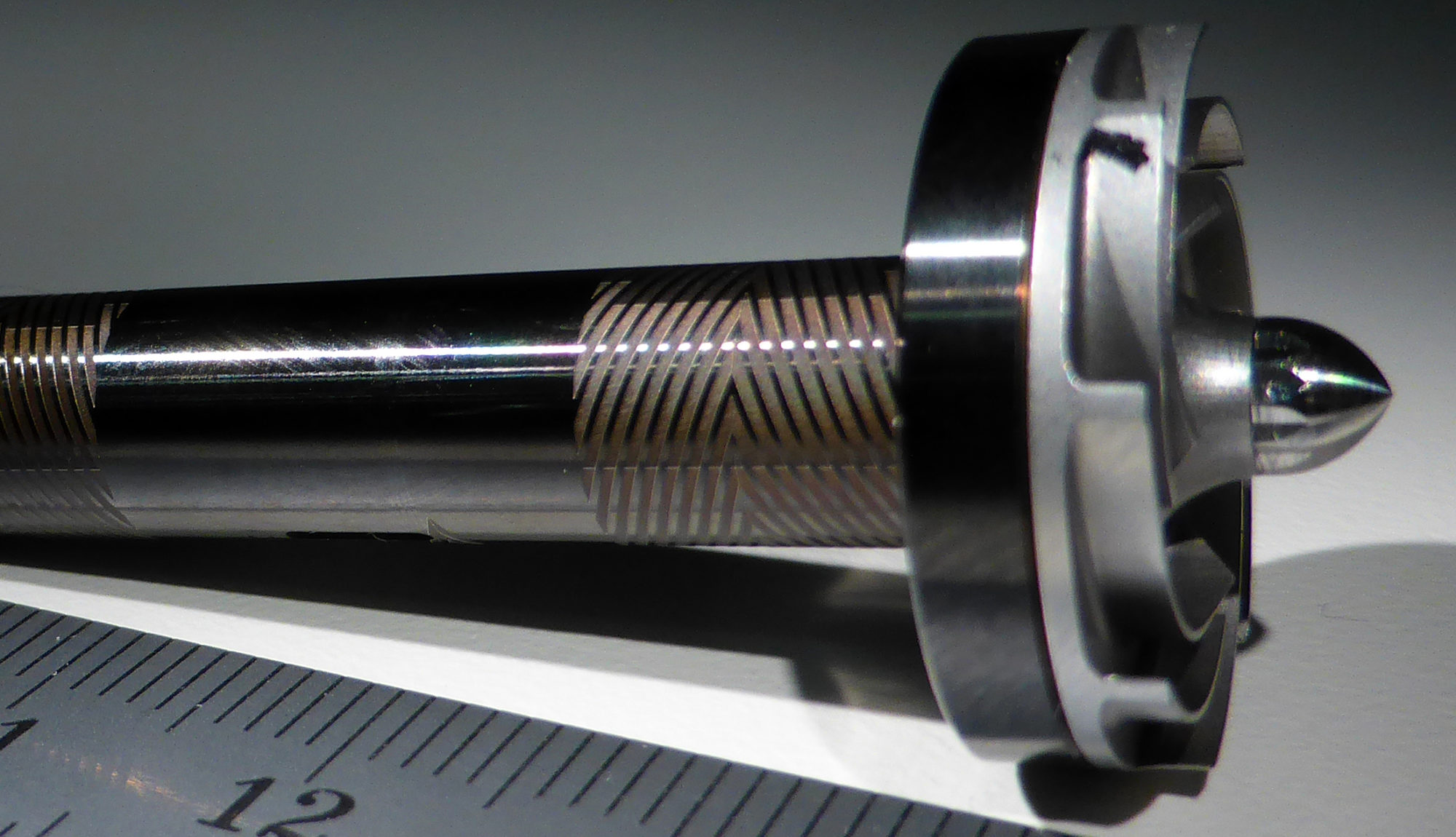

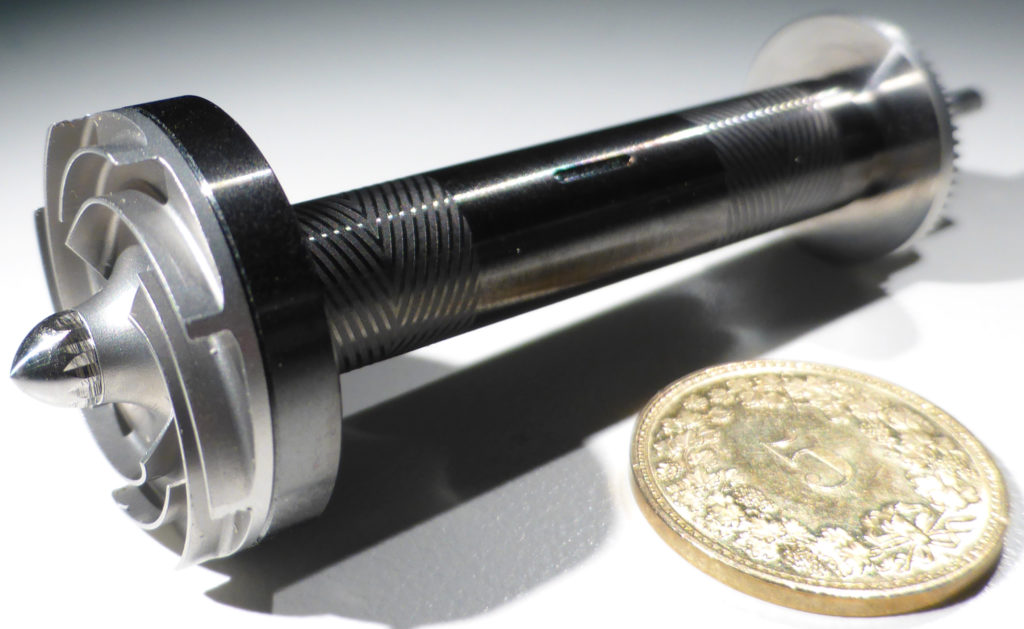

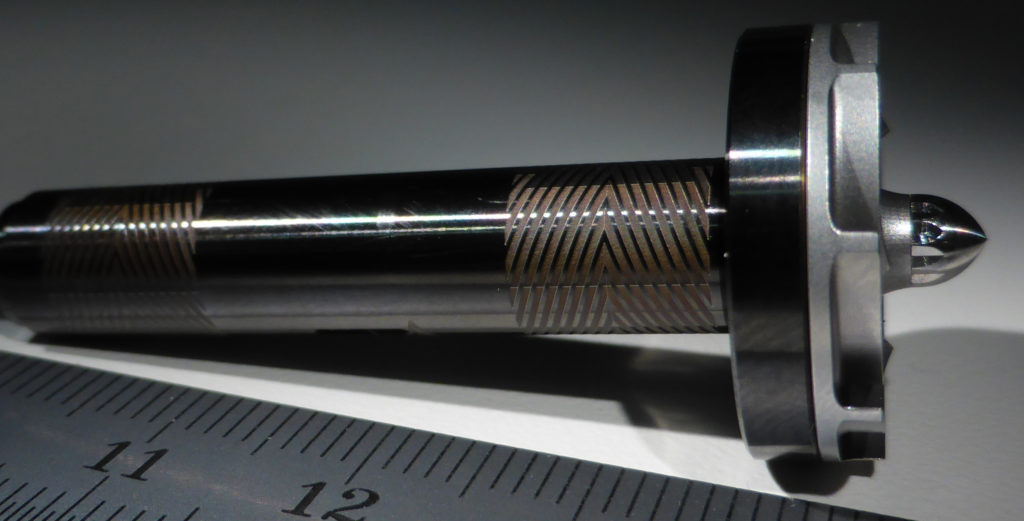

This FTU consists of a small-scale anode off-gas recirculation fan, a steam turbine, and a shaft with gas film bearings. The entire unit is manufactured by milling, turning, and surface finishing operations (i.e., grinding and honing) exclusively. The unit design is focused on low manufacturing cost, high lifetime, as well as oil-free and explosion-proof operation.

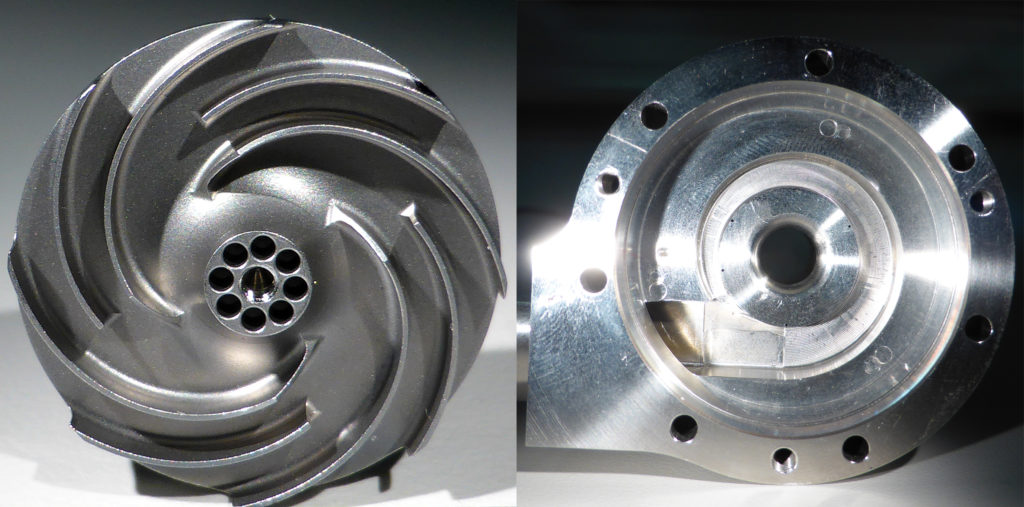

Fan: The radial inducer-less fan with a tip diameter of 19.2 mm features backward-curved prismatic blades (four main blades and four splitter blades). It is designed for SOFCs with up to 10 kW of electrical power. The design point is as follows:

- Pressure rise: 70 mbar

- Mass flow rate: 4.8 kg/h (anode off-gas mixture at 200 °C and 1.05 bar)

- Rotational speed: 175 krpm

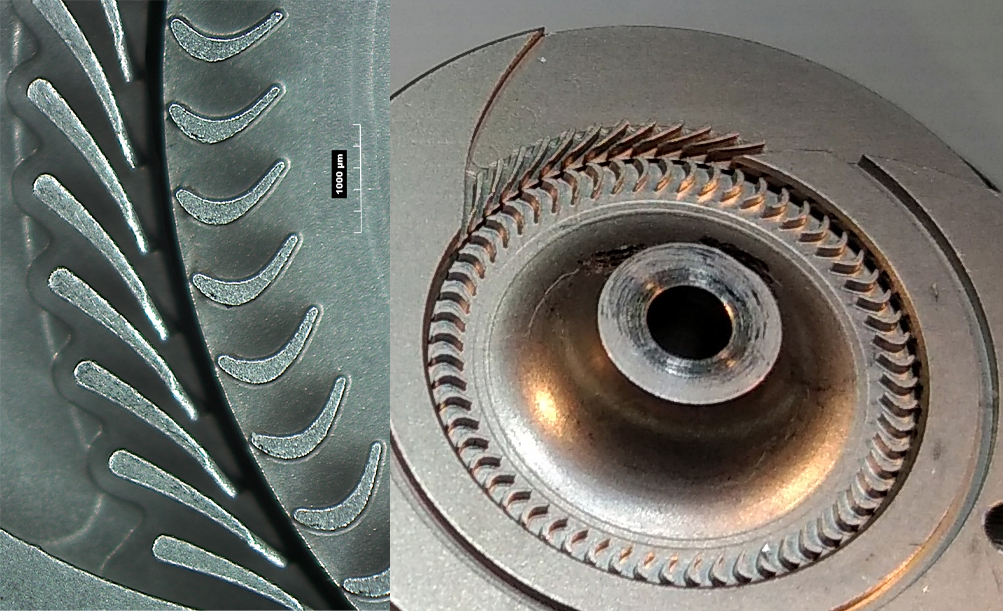

Turbine: The radial-inflow, partial-admission (21 %), and low-reaction (15 %) steam turbine has a diameter of 15 mm. It consists of 59 prismatic rotor blades with a radial chord of 1 mm and a blade height of 0.6 mm. The design point is as follows:

- Expansion ratio: 1.9

- Mass flow rate: 2.1 kg/h of water vapor (at 220 °C and 2.2 bar)

- Rotational speed: 175 krpm

- Power: 36 Watt

Shaft: The shaft features one single-sided spiral-grooved thrust and two herringbone-grooved journal gas film bearings. Nominally, these bearings operate with water vapor at temperatures of up to 220 °C and a rotational speed of up to 220 krpm.